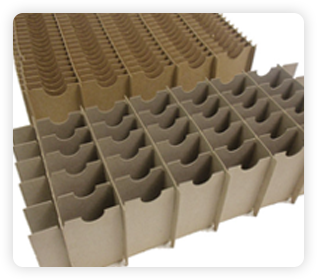

Corrugated board thickness is commonly referred to as flutes, with the major flutes including B flute, C flute, and Double Wall. B flute is the thinness, while common Double Wall is the combination of B and C flute. Flutes also come in a variety of tests, which create and even stronger partition, pad and specialty die cut. 125# test is the lightest, while the heaviest is 275# test. White One Side and White Two Side corrugated are also available in the specifications listed above. All flutes and finishes are in stock at all times.

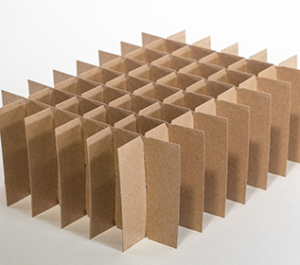

Corrugated partitions can receive certain optional features that serve any number of purposes. Directional notches can be cut into the corrugated box partition. This gives customers the ability to properly arrange partitions in a certain way on assembly lines or prior to packaging. Corner cuts are also available. This cut makes it easier to pack the box partition into a carton.

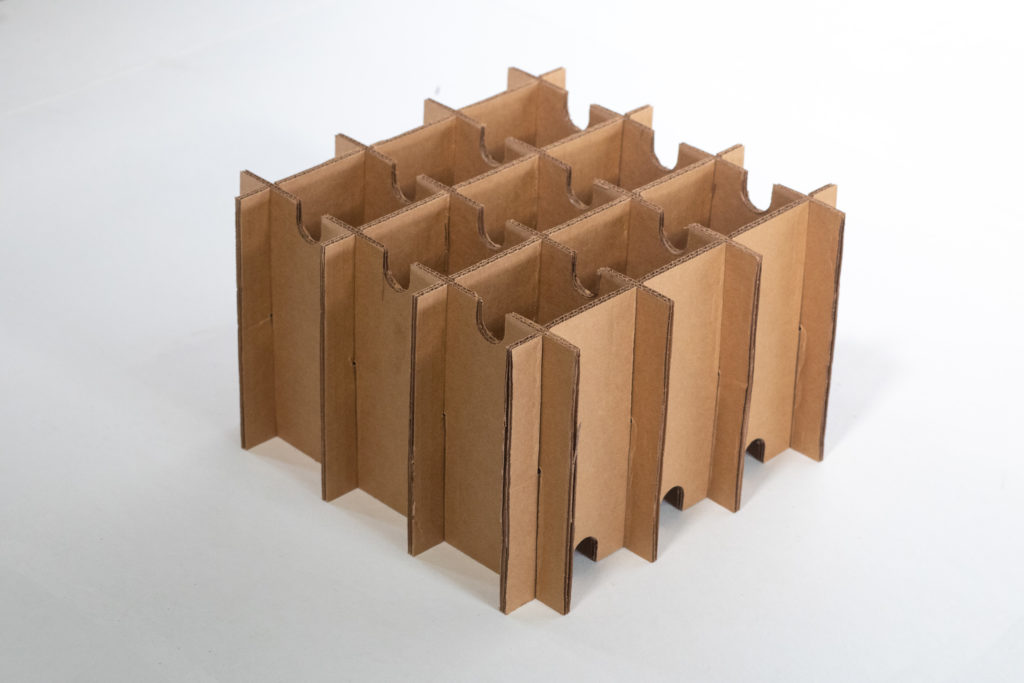

Corrugated partitions are well suited for large, awkward products. This is because corrugated partitions have the capacity to be larger than other type of partitions. Corrugated partitions can be as long as 56″, with a max height of 25″. Cell sizes can be as small as 3/4″ x 3/4″. Air cells, which are simply empty cells around the outside perimeter of the partition, can be created for extra protection. Corrugated box partitions are made to fit any standard or custom made carton. Engineers are always on hand to create new packs, revise old packs, or to simply answer any questions.

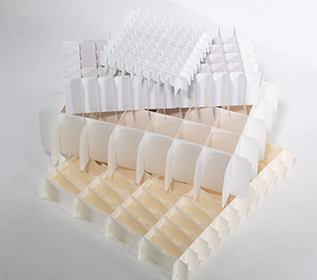

All corrugated partitions will arrive assembled. They will be bundled and secured to a pallet. The pallet will be marked with the customers information.